At the design and design stage, BIM identifies potential design inconsistencies and problems related to the feasibility of the project, thereby preventing costly corrective improvements; and this improves the tender process by making information more transparent and accessible.

An interesting example is the Crossrail project, one of the largest and most complex infrastructure projects in the world, involving the construction of a new major metro line through London: designers and engineers use a centralized set of linked BIM databases to integrate about 1.7 million CAD files into a single information network.

During construction, drones inspect and inspect the construction site. 3D printers manufacture many building components in advance. GPS and Radio Frequency Identification (RFID) are used to track materials, equipment and workers to then optimize flows and inventory levels. Robots and autonomous vehicles do most of the actual construction work. 3D laser scanning or aerial photography is used to compare work in progress with a virtual model, which allows you to quickly adjust the course and minimize corrective work.This helps with the management of a construction project, and makes it possible to quickly respond to project changes.

Take the example of a Japanese equipment manufacturer that has developed fully autonomous bulldozers controlled by drones that map the terrain in real time and provide workload data. During the operational phase, the built-in sensors continue to monitor any given part of the asset, checking wear, facilitating preventive maintenance and constantly updating the central database. Augmented reality is used to guide repair teams.In these works, it is especially important to note the need for a large amount of administrative coordination work – this is the basis for managing the construction project.

Big data on traffic, electricity consumption, etc. is collected digitally and subjected to advanced analytics in order to optimize the decision-making process and generally improve work efficiency. Data collection, analysis, forecasting and planning are special components of project management.

As an illustration, consider the approach taken by the Japanese company NTT, a provider of construction services, to the inspection, maintenance and repair of its research facilities: by integrating the BIM model into the building's facilities and assets management system and using this combined resource wisely, the company has reduced operating and maintenance costs by about 20%.

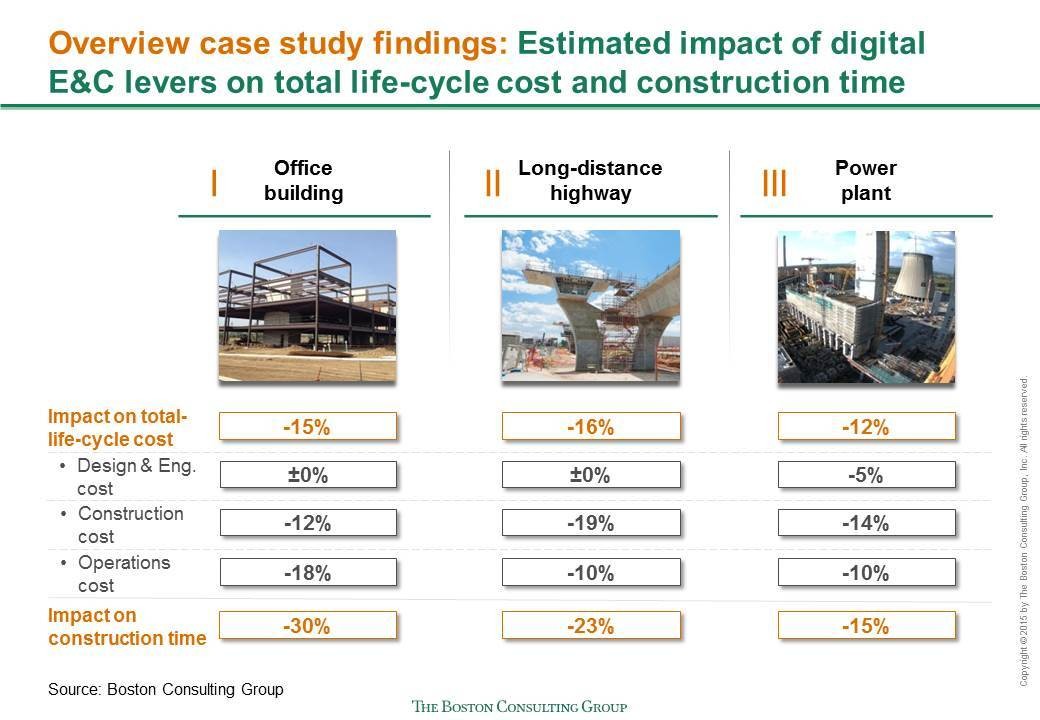

According to The Boston Consulting Group, within ten years, full-scale digitalization will lead to huge annual global cost savings. For non-residential construction, these savings will be from 0.7 trillion to 1.2 trillion dollars (from 13% to 21%) at the design and engineering and construction stages; and from 0.3 trillion to 0.5 trillion dollars (from 10% to 17%) at the operational stage.

Today we are ready for technological innovations and digitalization of the construction project in Kazakhstan.

The ETHOS Software Package: "Construction Management" is an information complex that allows you to plan, monitor and analyze and predict the results of a construction project in Kazakhstan. More information about the software package: https://acpm.tech/etos

Saniya Ayambekova

Director

Advanced Controls & Project Management